Management System

MES Management System

Real-time Tracking

Machine Data

Process Quality Control

Visual Kanban of Production Process Quality

● Production big data visualization dashboard

Real time display of production models, planned output, completed output, completion rate, and other production information for each production line;

● Fully automatic pressure management intelligent large screen

Real time display of production output, production qualification rate, and other information for each fully automatic crimping machine

Visual Kanban of Production Process Quality

Real time display of comprehensive quality information in the workshop

● Equipment status visualization board

Real time display of the startup status, production utilization rate, and other information of each device

Press the machine data

The production management system can collect real-time production data and pass rates of each terminal crimping machine, upload them to the database in real time, and summarize them on the production screen for visual management.

Visual Kanban of Production Process Quality

Production process quality visualization dashboard, which comprehensively displays quality information such as the pass rate of main production workstations and the ranking of production line quality.

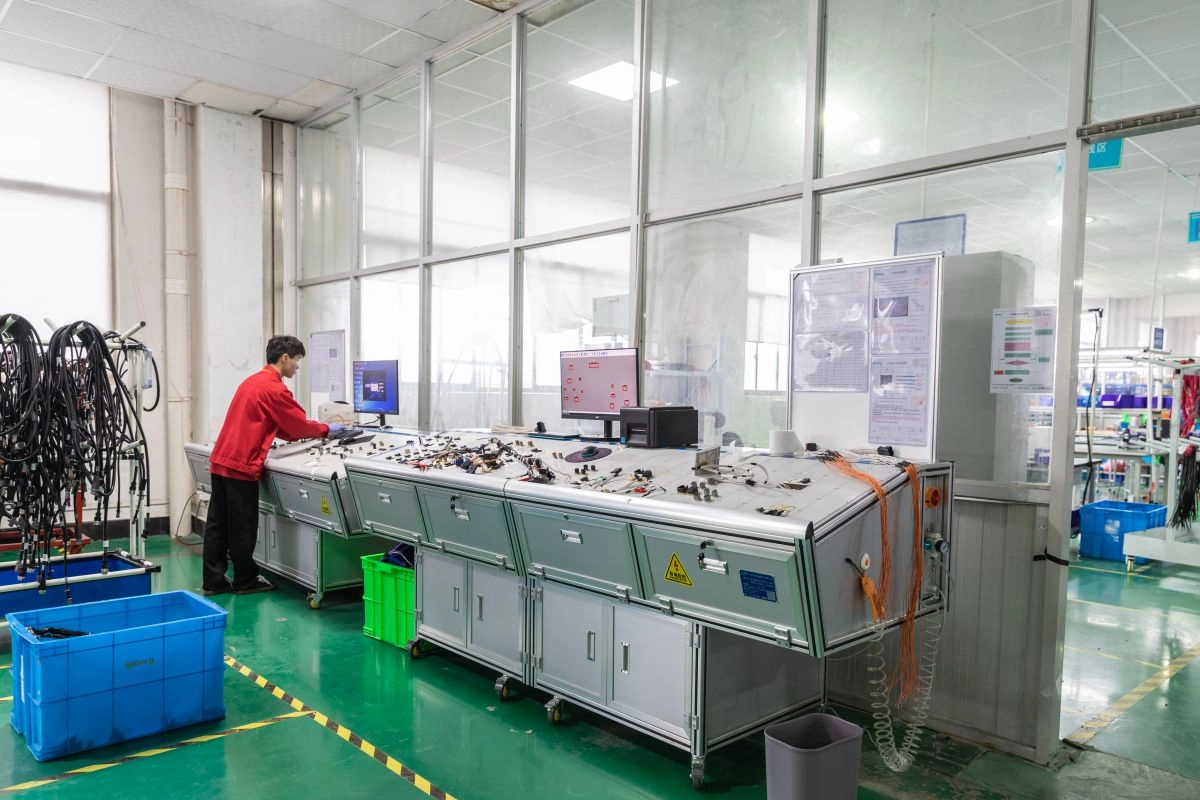

Production Workshop

At present, Iberg Electric is divided into two factory areas. The first factory covers an area of 15 acres with a workshop area of 7500 square meters, while the second factory has a workshop area of 5000 square meters. We have a production capacity of 65 fully automatic terminal machines, 85 semi-automatic terminal machines, 21 fully automatic assembly production lines, and a daily output of 12000 sets of electric vehicle wiring harnesses, 4000 sets of household appliance wiring harnesses, 150000 sets of printer wiring harnesses, and 200 sets of engineering vehicle wiring harnesses. Intelligent and automated upgrading of equipment, always paying attention to the development of industry automation, jointly developing automation equipment, replacing skilled physical labor with machines, and normalizing work;

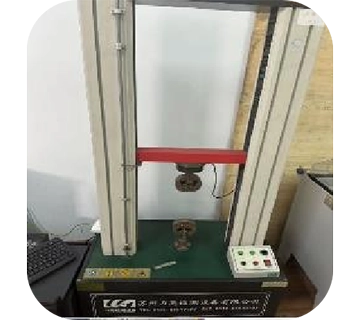

Test Equipment